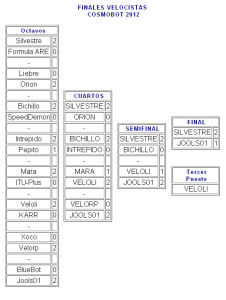

Silvestre became champion of the Cosmobot 2012, one of the main robotics contests in Spain, after a really tough competition.

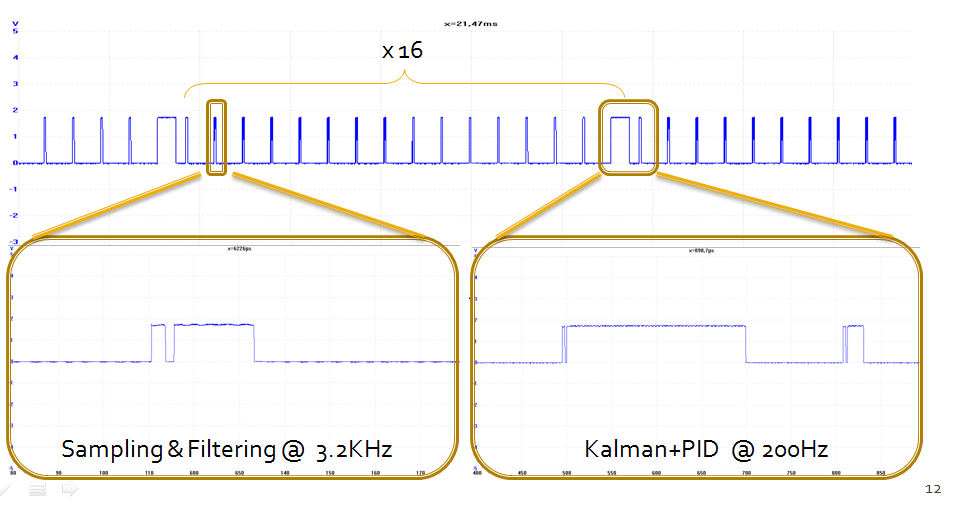

During the qualifying session in the morning, Silvestre made the fastest time with an average speed of 2.45 meters per second. Later in the evening, 16 robots went into the knockout phase and Silvestre had to make the most out of itself to push into an speed of 3 meters per second during the final round.

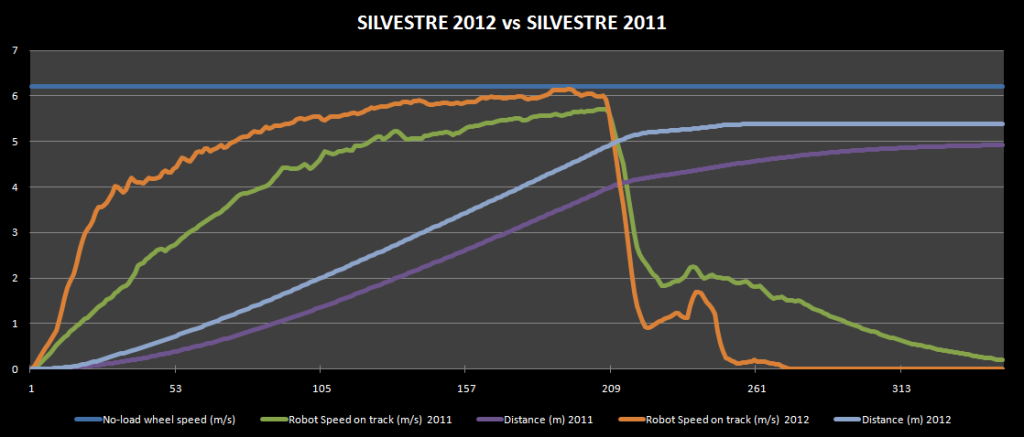

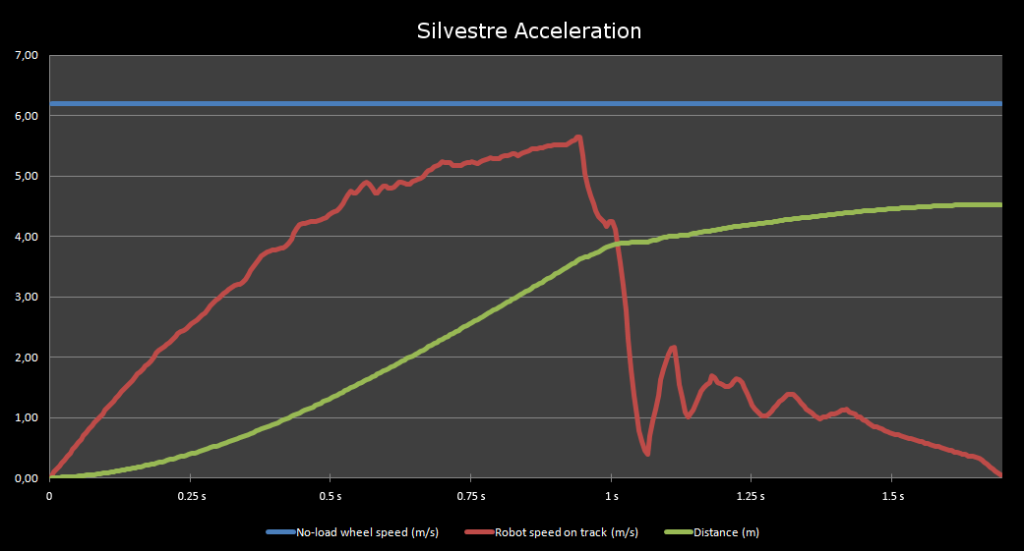

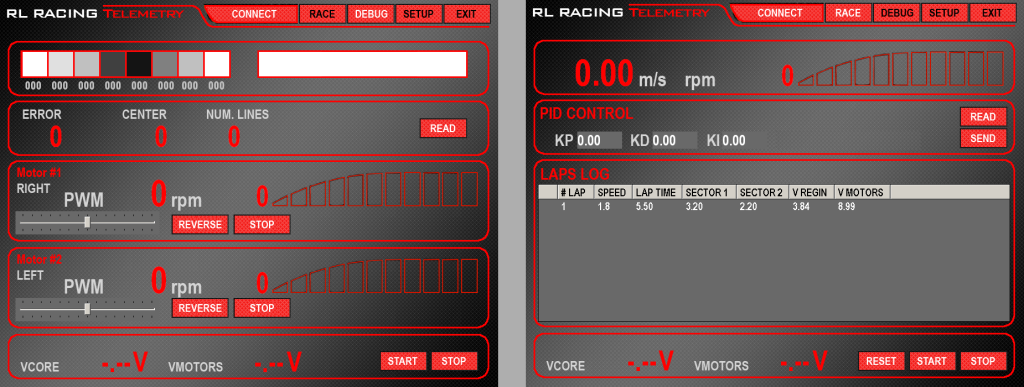

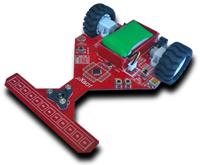

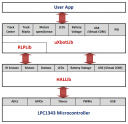

The strongest point of Silvestre was, undoubtedly , his ability to learn the track and accelerate/brake at the right moments. Unlike past years, Silvestre doesn’t need any parameter to be entered manually but he will dynamically extract the key parameters of the track thanks to the encoders and inertial sensors. After the track’s been successfuly learnt, he will store it into memory for later runs in order to save the learning process every time. However if the data reported from the sensors is different from the expected track, he will learn again or modify it accordingly allowing him to self-adapt to changing conditions.

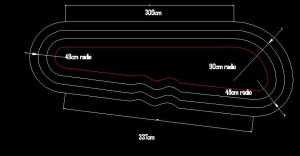

The track was really good for our algorithm even though the zig-zag zone was tricky but also a good sucession of events that provided a more accurate positioning 🙂 The rules of the contest state that if a robot touches the internal lane, it would get disqualified but nothing prevents a smart robot from going through the zig-zag area as if it was a straight.

Silvestre was able to recognize the zig-zag area and, depending on the selected profile, he would “patch” the stored track to navigate inertially without reading the line, strictly during the zig-zag turns. This involves a risk because the top speed was about 6m/s and the navigation had to be as accurate as possible but it was robust enough so I used it on the final round ![]()

Semifinals:

Finals:

I don’t know what happened during the first round but Silvestre missed the line (Murphy’s law pushed him?) and started to learn the track again but, before this happened, the rival caught him up. The next two rounds, everything worked great and Silvestre won the championship!

After the contest, people wondered if Silvestre could learn the track clockwise and here’s the video:

Another video of Silvestre from another angle:

Slow motion video of the zigzag turns:

And below is the proof that what the videos show is not easy at all and took many hours analyzing data and trying:

New vs. used wheels after some training days

Unfortunatelly, my friend Alberto and I, don’t have as much time as we’d like to spend on the robots but we’re still enjoying competing and getting home at 2AM after a 20-hour of hard work the day before the competition 🙂 It’s great to see how racing robots have improved during the past two years and how innovative one must be in order to keep up pace.

UPDATE: video of the two semifinals and the final. Awesome!

Daniel