I’ve started to build some sort of two-wheel Balancing Robot and before getting the party started I’m having to deal with mixing up the data gathered from my inertal sensors.

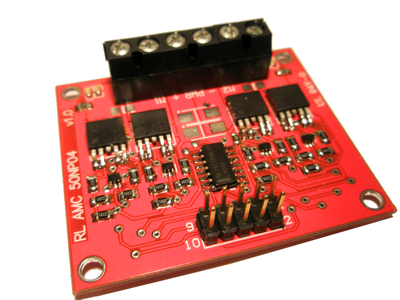

My homebrew IMU (Inertial Measurement Unit) is composed by one 3-axis accelerometer and 1-axis gyroscope. The gyro sensor’s got an analog output (.67mV per degree/s) and the accelerometer’s got an i2c interface. I would love to share its part number with you but, since I liked this unit to be as cheap as possible, the sensors were ripped out (and reverse-engineered with a logic analyzer) from a cheap PS3 gamepad bought on eBay ;).

Since the output of the gyro sensor is ‘too low’ for my ADC, I built a simple non-inverter amplifier and a low pass filter with a cutoff frequency of 1KHz. Also I placed a high pass filter (cutoff frequency at .3Hz) in order to compensate the temperature drift. The data from the accelerometer’s digitally filtered on the microcontroller with a simple 1st order Butterworth filter.

The main idea of this kind of robots (inverted pendulum) is to measure the tilt angle in order to drive the wheels just below the mass. The higher the center of gravity, the easier balancing will be. Why do we need both an accelerometer and a gyro?

– The acclerometer senses not only the gravity (tilt) but the acceleration forces on its axis. So it would be useful if it was static (no acceleration due to movement).

– The gyro outputs angular velocity (degrees per second) and it’s not sensitive to acceleration. In order to get the angular position we have to integrate this signal. However this will drift over the time and the estimated tilt angle wouldn’t be accurate after some seconds.

The ‘trick’ is to take out the best of each sensor: the long-term information from the accelerometer and the short-term response from the gyro sensor. One way to do this is using a ‘black-box’ known as Kalman Filter (if you are brave enough, have a look at the theory; I’m not :)) which mixes up both signals predicting the actual tilt angle.

I got some source code of this filter from rotomotion (http://scratchpad.wikia.com/wiki/RotomotionCode) and pushed it directly onto my microcontroller. The sensors are sampled at 50Hz and fed to the KF at the same rate. In the next plot you can see the raw tilt angle (atan2(raw_accy, raw_accx)), the integral of the gyro sensor (using the trapezoidal rule) and the output of the Kalman Filter.

As you can see, the raw tilt angle is a little bit noisy while the gyro integration is very clean. Also, there’s a lot of drift in this signal but magically the KF manages to estimate the angle very accuratelly and free of noise.

Now it’s time to try the filter with stronger movements and vibrations before feeding its output to the PID which will – hopefully – make the robot balance 🙂

I ‘ll post more on this soon!

Daniel